How robotics and automation can benefit from 3D printing, explains Replique

Robotics Business Review

JULY 6, 2024

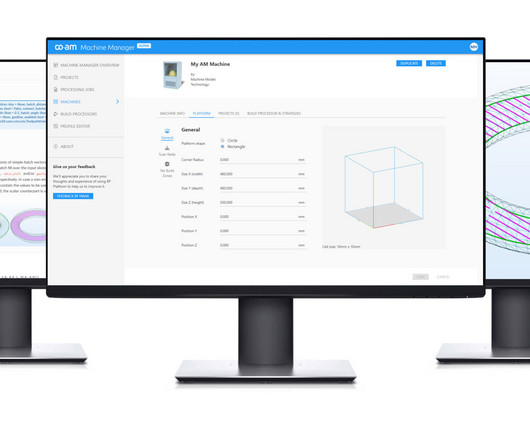

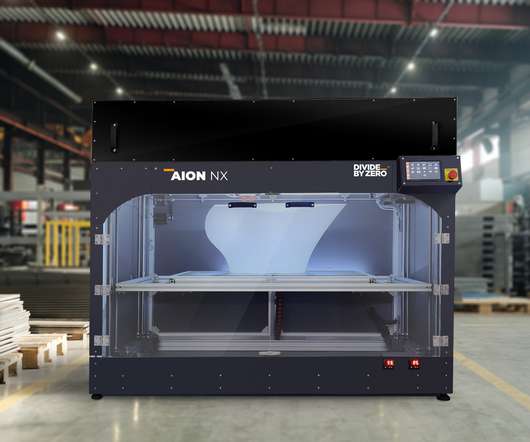

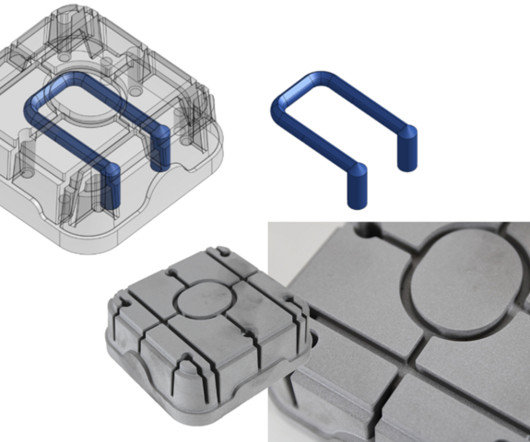

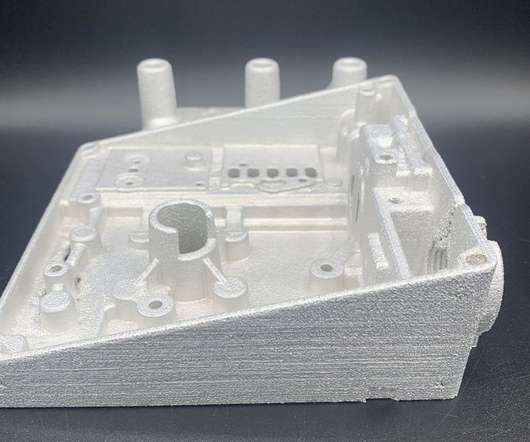

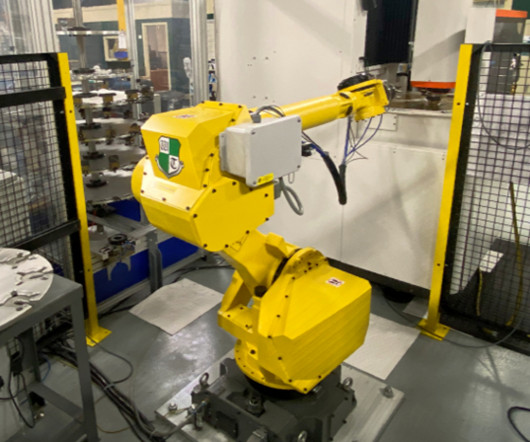

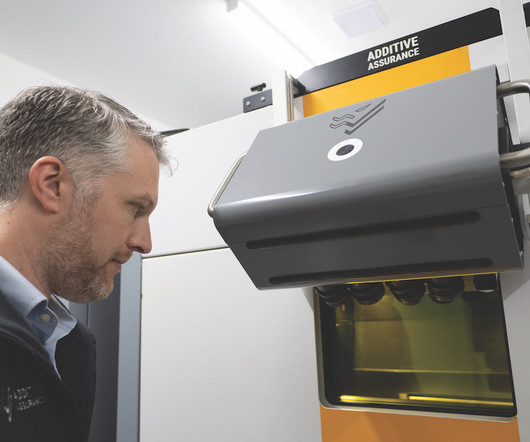

Robotic arms in large-scale 3D printing deposit materials layer by layer, transforming production. Source: Replique In the realm of modern manufacturing and automation, the integration of robotics continues to redefine industry standards. One technology that is pushing the boundaries of what’s possible is 3D printing.

Let's personalize your content