Innovation With the Additive Advantage

Additive Manufacturing

JULY 28, 2022

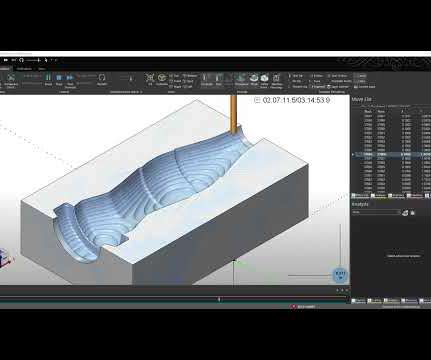

Additive manufacturing (AM), more commonly known as 3D printing, is an innovative process where objects are created one layer at a time. 3D Printing in Action. From 3D printing rocket motors to using advanced materials to produce aircraft parts, the company uses AM across the enterprise.

Let's personalize your content