8 Ways the Plastics Industry Is Using 3D Printing

Mold Making Technology

APRIL 3, 2024

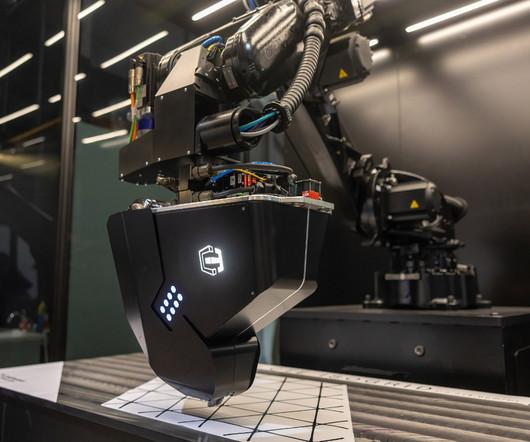

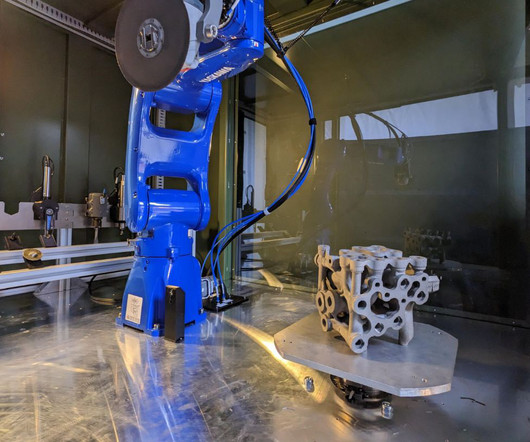

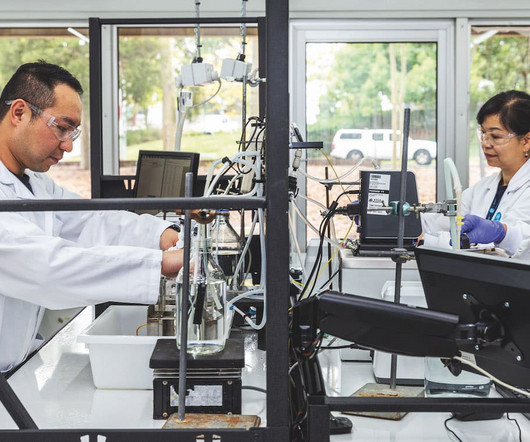

Once relegated to rapid prototyping, 3D printing technology has now advanced far beyond the design studio. At NPE 2024: The Plastics Show , 3D printing and additive manufacturing (AM) suppliers will be highlighted in the Advanced Manufacturing Zone , while AM users will take to the stage for Wednesday’s 3D Printing Workshop.

Let's personalize your content