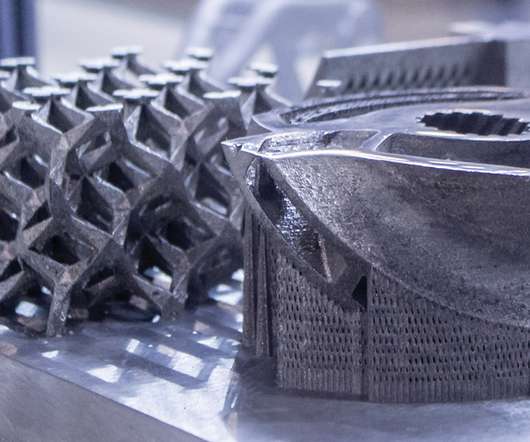

Fortius Metals secures $2 Million Additional Funding to Support Advanced Metal 3D Printing

Fabricating & Metal Work

DECEMBER 7, 2024

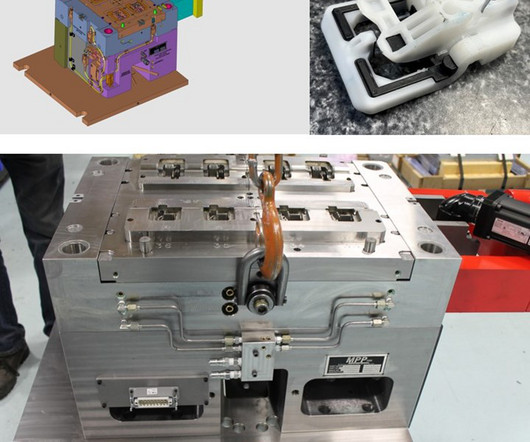

an innovative metal 3D printing company, is pleased to announce the successful closure of an additional $2 million in their Seed+ funding, bringing the total raised in the financing round to $5 million. Fortius in-house capabilities include wire manufacturing as well as wire arc and wire laser (wire DED) large format 3D printing cells.

Let's personalize your content