Shop Tour Video: From Garage Shop to Leading Aerospace Supplier

Modern Machine Shop

JANUARY 7, 2025

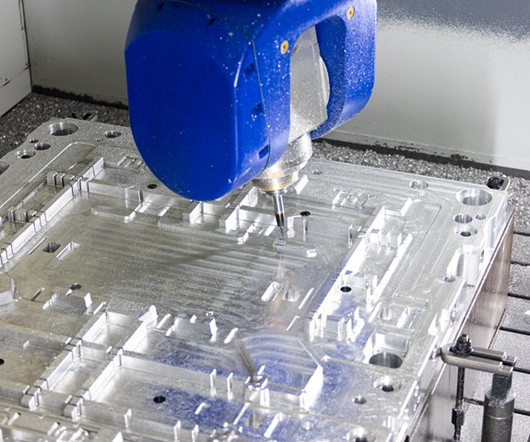

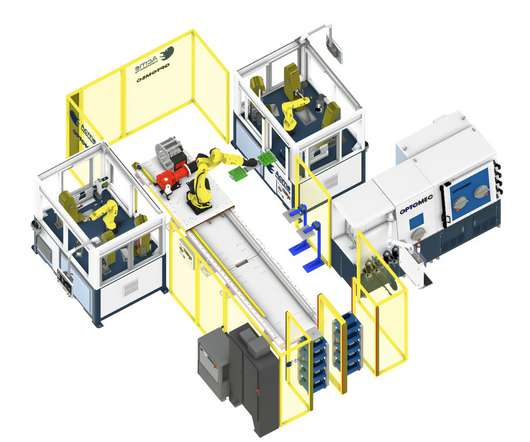

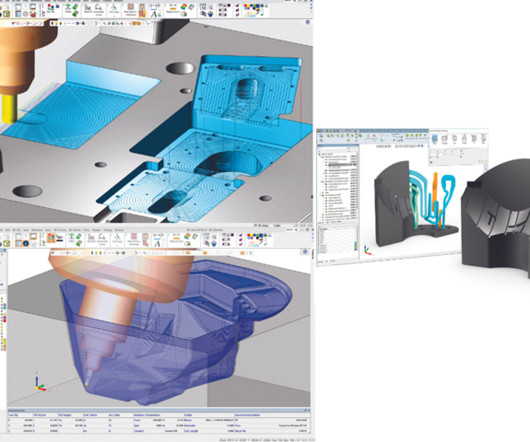

Superior Joining Technologies is a family-owned job shop that transformed from a humble garage startup into a key aviation, aerospace, and medical industry supplier. And you’ll discover how their unique blend of machining and welding expertise drives success in aerospace and beyond. It gives us more control of lead times.

Let's personalize your content