Multi-metal 3D printer to boost Australia’s aerospace manufacturing

Manufacturer's Monthly

MARCH 27, 2024

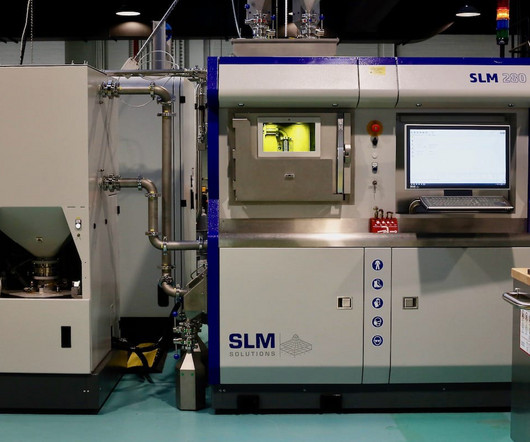

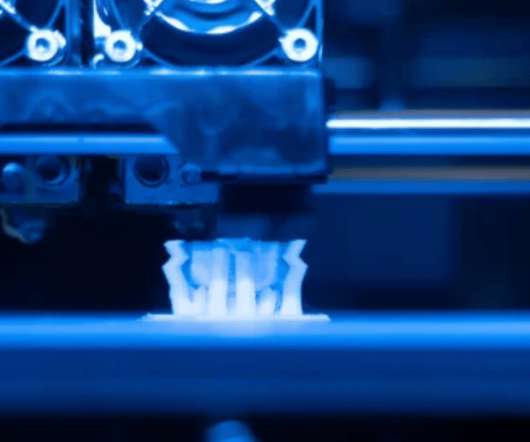

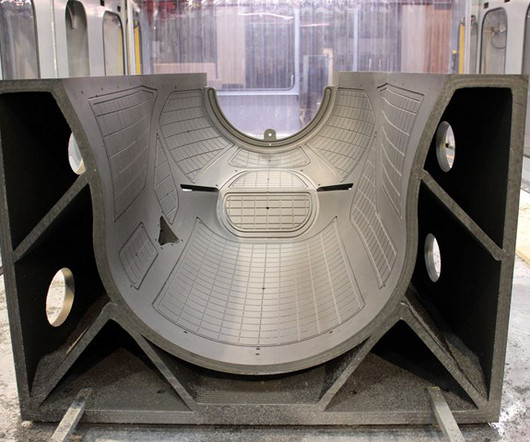

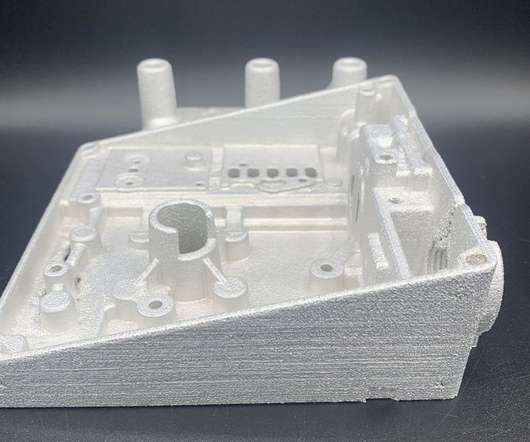

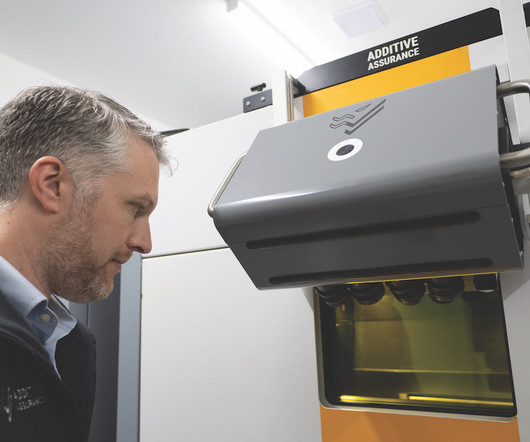

Image: Nick Rains/CSIRO The commissioning of a new multi metal 3D printer in Melbourne as part of the iLAuNCH Trailblazer initiative is set to make space missions more affordable and efficient by creating lighter, faster and more robust aerospace components. and weight reduction of 31 per cent with ASCO, a Belgian aerospace company.

Let's personalize your content