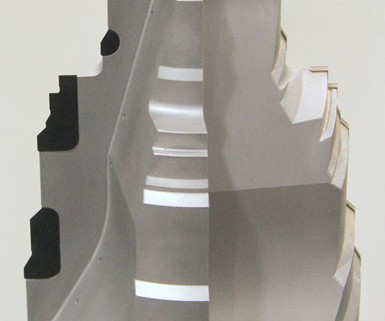

Large Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

Mold Making Technology

MAY 2, 2023

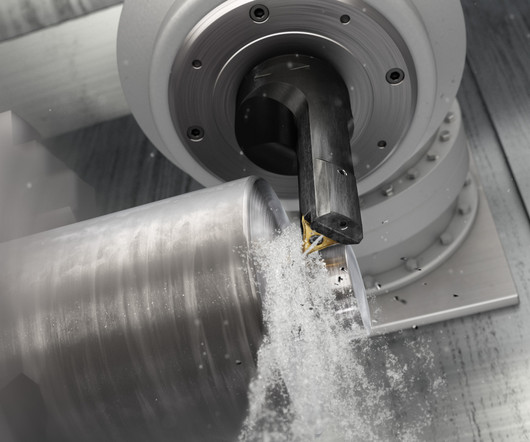

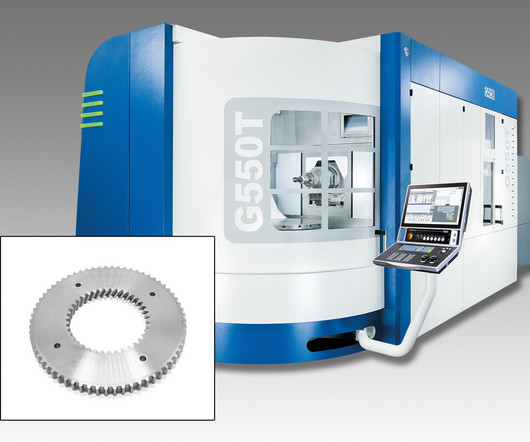

Results: Controlled dimensionality and acceptable cycle times were achieved for these large parts in an abrasive crystalline polymer. Still another concern was achieving acceptable cycle times while extending the life of the tool and preventing galling by this abrasive polymer.

Let's personalize your content