Watch Out adds autonomy to CNC cells for precise production

Robotics Business Review

JANUARY 21, 2025

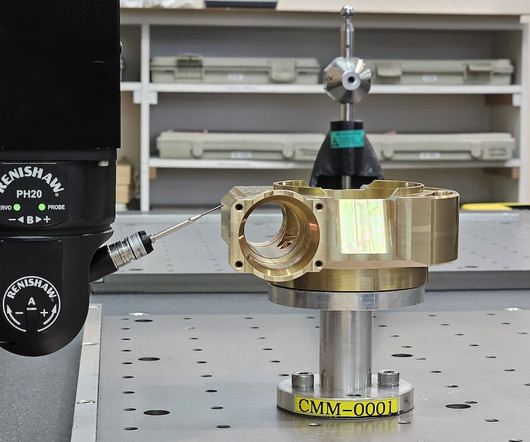

Watch Out visualizes a highly automated workcell that can fit into a container. Source: Watch Out Manufacturers face widespread shortages of skilled labor, but more intelligent automation could alleviate the problem, according to Watch Out. ” In 2016, Laporte and Perret launched Watch Out, and Mariette joined them in 2019. .

Let's personalize your content