ARC hub for Australian steel innovation launches in Illawarra

AU Manufacturing

OCTOBER 16, 2022

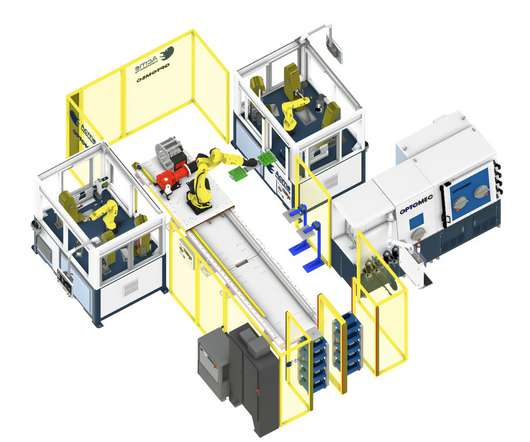

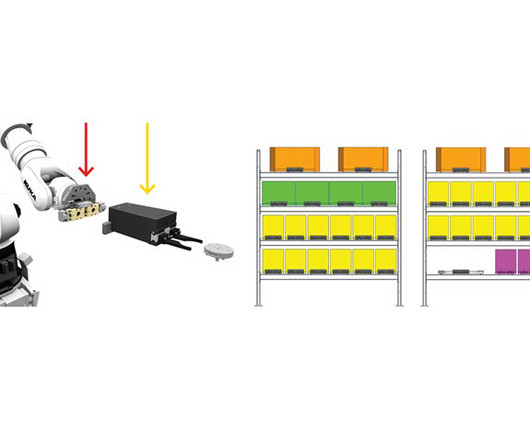

The new ARC Hub seeks to deliver various innovative research outcomes to address the next generation of functional steel products and advanced manufacturing processes. This would support the transition of the national steel manufacturing industry to a more sustainable future, UOW said in a press release. .

Let's personalize your content