Faster Programming and Training Helps Automotive Shop Thrive

Modern Machine Shop

OCTOBER 1, 2024

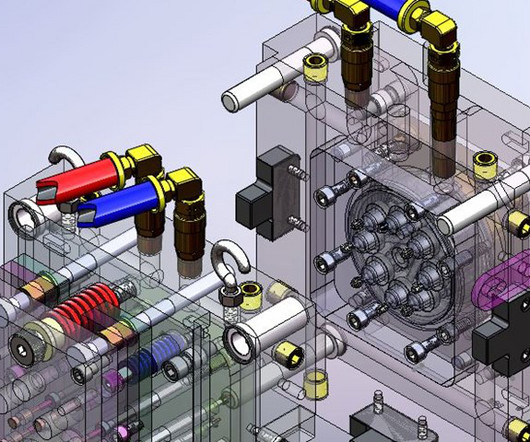

Collision detection features in SolidWorks save Speedway Motors a lot of time and scrap during prototyping, as the software can automatically detect when tooling and fixture interfere with each other. In 2009, Speedway Motors of Lincoln, Nebraska, had only two CNC machines to machine its aftermarket car parts.

Let's personalize your content