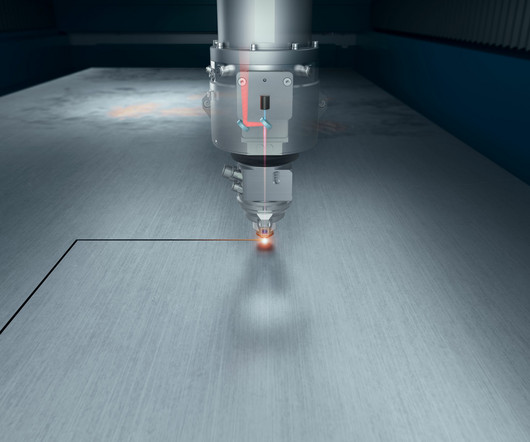

Graphene oxide study strengthens the case for smart concrete

Manufacturer's Monthly

DECEMBER 4, 2023

Engineers have added graphene oxide to cement mixture to make stronger 3D printed concrete that is easier to print, paving the way to create potential ‘smart’ walls that can monitor cracks. This strong bonding can improve the overall strength of the concrete.

Let's personalize your content