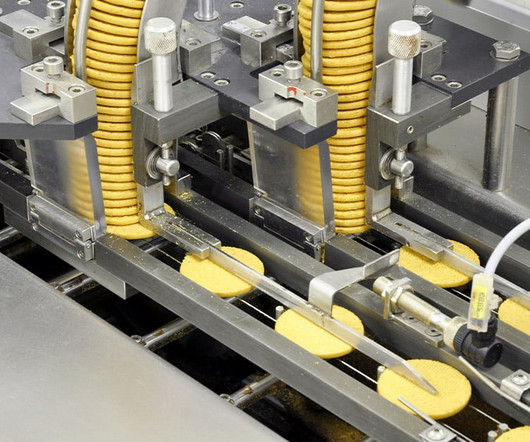

Food & Beverage Condition Monitoring & Predictive Maintenance

ATS

MARCH 26, 2024

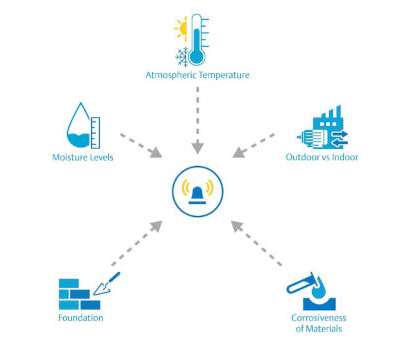

In highly competitive industries, that creates pressure to do the work as quickly and effectively as possible. Predictive maintenance is about anticipating when machinery needs attention based on history and data from condition monitoring sensors. This mandates documentation along with equipment cleanliness.

Let's personalize your content