Maintenance Troubleshooting: A Comprehensive Guide for Optimized Industrial Operations

ATS

JANUARY 13, 2025

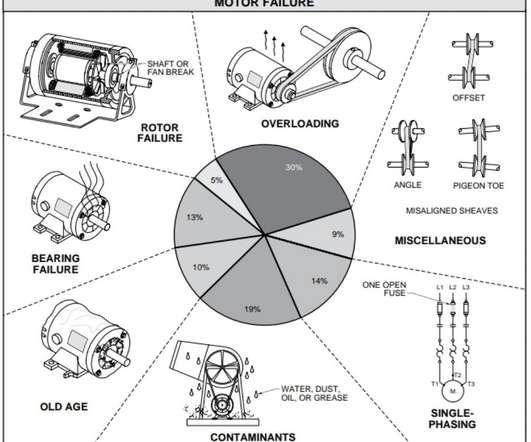

Introduction to maintenance troubleshooting Most industrial manufacturers use preventive maintenance techniques to ensure production assets perform as required. Troubleshooting differs from other aspects of asset management and maintenance in that at the outset its unclear what work is needed.

Let's personalize your content