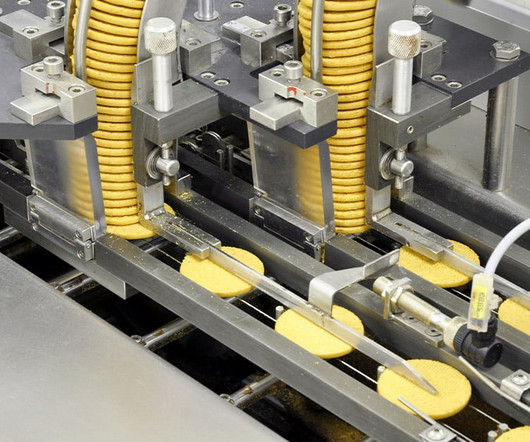

Food & Beverage Condition Monitoring & Predictive Maintenance

ATS

MARCH 26, 2024

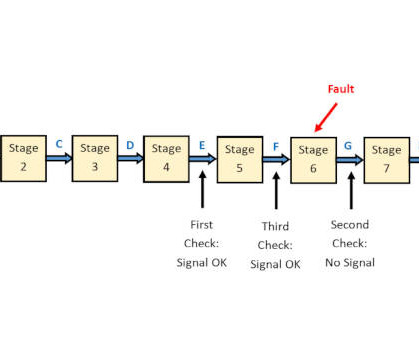

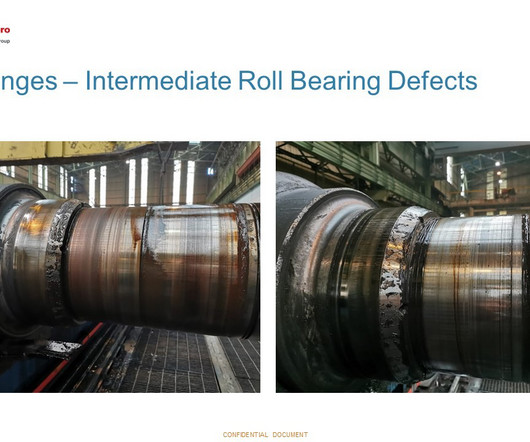

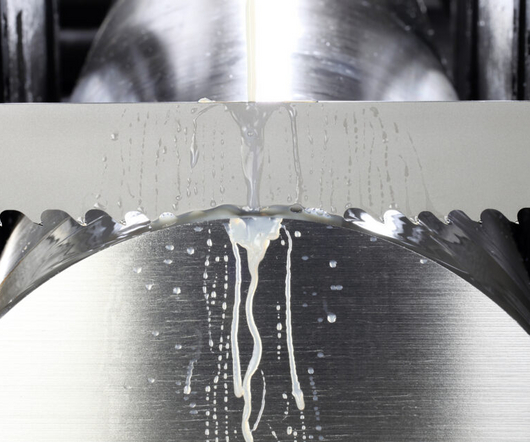

Predictive maintenance is about anticipating when machinery needs attention based on history and data from condition monitoring sensors. The consequences are seen in: High speed machinery: Speed drives down costs, but parts tend to wear quickly under high loads.

Let's personalize your content