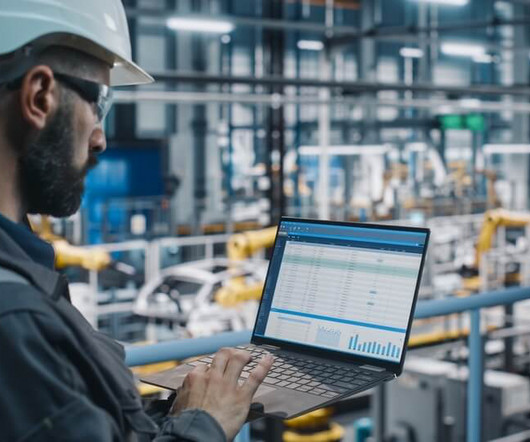

Fictiv Launches Large-Scale CNC Parts Manufacturing

Manufacturing Tomorrow

JUNE 12, 2025

Login --> White Papers Events Calendar Featured Products Company Directory Publisher #5: ManufacturingTomorrow Zone #111: MT 728x90 Top of Page Size #19: Jumbo Banner [728x90] --> Publisher #5: ManufacturingTomorrow Zone #112: MT Page Peel Secure (HTTPS): enabled --> Online Trade Magazine - Industry 4.0

Let's personalize your content