How a collaborative approach is driving Ireland from Industry 4.0 to Industry 5.0

Control Engineering

JULY 17, 2023

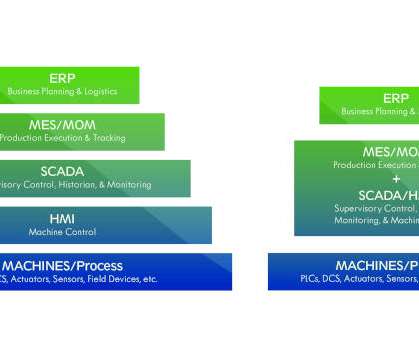

Industry 5.0 insights Whereas Industry 4.0 refers to the use of digitalization, data connectivity and OT/IT interconnection to optimize manufacturing operations, Industry 5.0 The blessing and the curse of Industry 5.0 At the same time, because every Industry 5.0 MORE ANSWERS Keywords: Industry 5.0,

Let's personalize your content