AMRs and AMVs Create Safer Surroundings and Adjust Workflows Quickly

Fabricating & Metal Work

APRIL 22, 2024

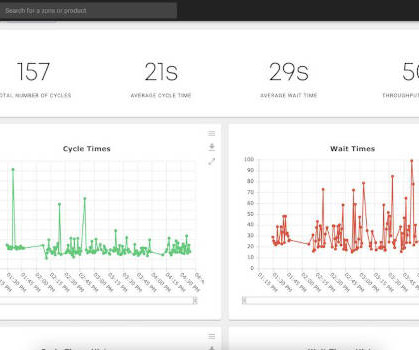

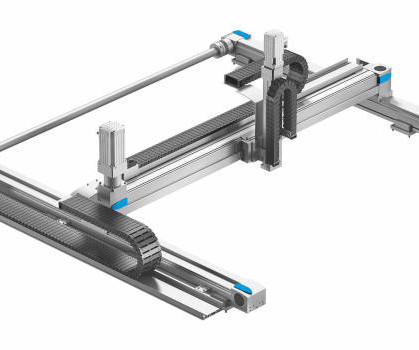

AI-enabled mobile robots can transform sectors like discrete manufacturing, logistics and laboratories,” Segura said. When cycle times require high-speed travel, front and rear-mounted laser scanners ensure safe operation in all travel directions. An integrated lifting device lifts up to 60 mm in under three seconds.

Let's personalize your content