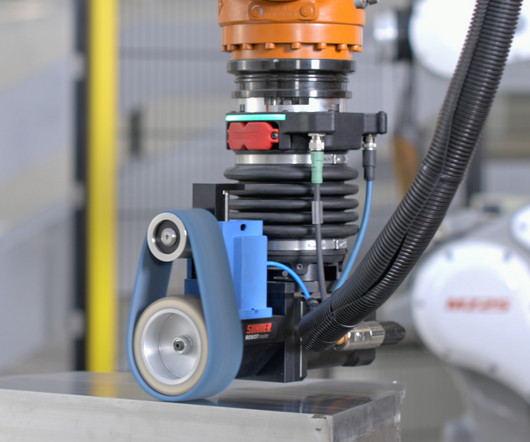

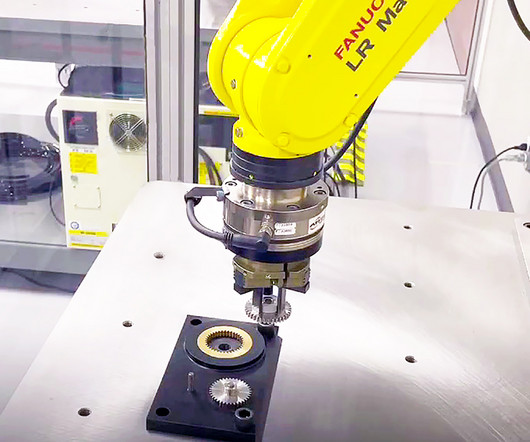

Suhner to Unveil New Robotic Electric Force Compliance System at AUTOMATE

Fabricating & Metal Work

MARCH 28, 2023

Recognizing the role robotics plays in adding efficiency and lowering production costs for manufacturers of all types and sizes, Suhner continues to expand its robotics offering. An advanced control algorithm then dynamically adjusts force and automates grinding processes based on pre-programmed parameters. The result?

Let's personalize your content