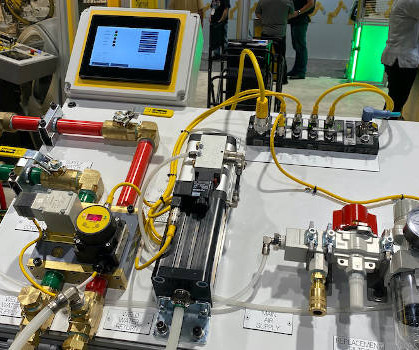

Visibility & Resiliency: Letting Your Factory Work For You

Cisco Industrial Automation

SEPTEMBER 14, 2022

Industry research shows that by 2023, 30% of manufacturers will enhance their shop floor digital twin with real-time signal transponder data, leading to an 80% reduction in logistic bottlenecks in shop floor and storage areas – Source: IDC FutureScape: Worldwide Manufacturing 2021.

Let's personalize your content