The big picture: Trends in artificial intelligence for manufacturers

Automation Mag

NOVEMBER 29, 2022

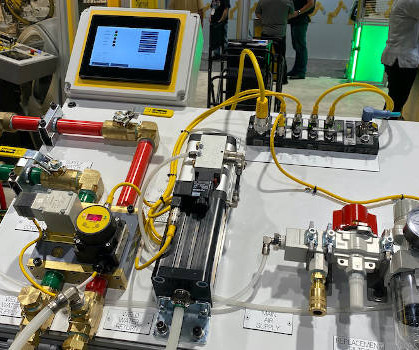

The solutions in development are across the manufacturing value chain. AI can predict maintenance failures earlier and schedule a diagnostic or repair at a convenient, or non-bottleneck time. This bottleneck is prohibitive for many companies for a variety of reasons.

Let's personalize your content