The Future of Smart Supply Chain with Industry 4.0

ATS

NOVEMBER 9, 2022

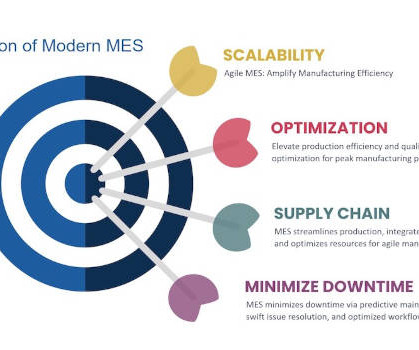

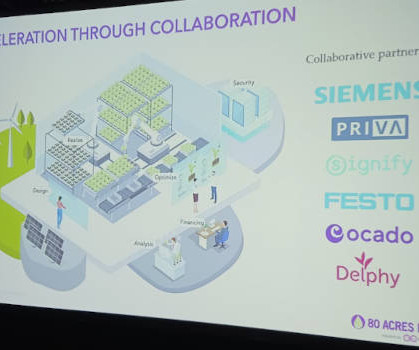

The importance of the supply chain is most easily illustrated by the vast scale of the repercussions that follow when supply chain problems occur. Supply chain digital transformation — driven by Industry 4.0 Digital transformation in logistics and supply chain. developments.

Let's personalize your content