Building a traceability 4.0 foundation for automation

Control Engineering

MARCH 27, 2023

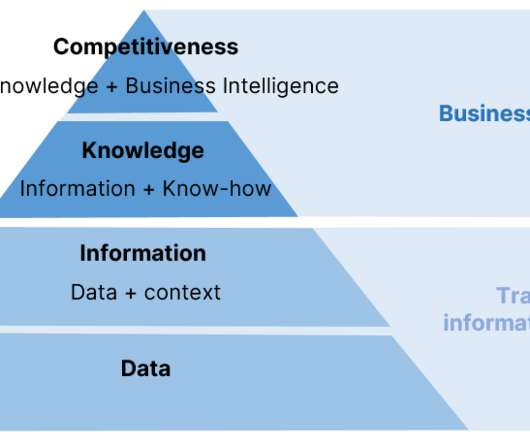

The ability to gather and record data on the whereabouts and timing of works-in-process undergoing a specific manufacturing operation or finished products making their way through the supply chain is essential for ensuring quality, identifying bottlenecks and minimizing product waste during recalls. Industry 4.0

Let's personalize your content