Automotive lidar’s role growing because of increased use of autonomous vehicles

Control Engineering

MAY 26, 2023

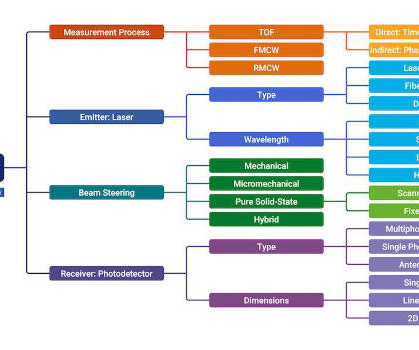

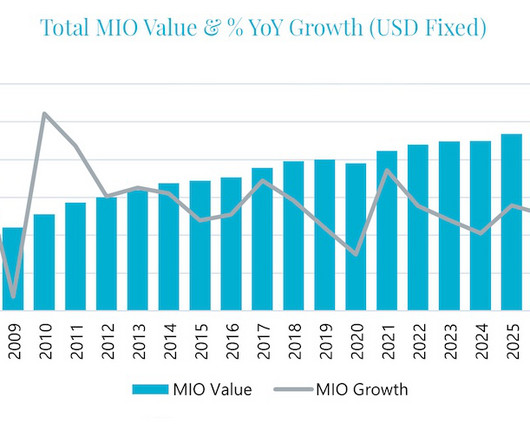

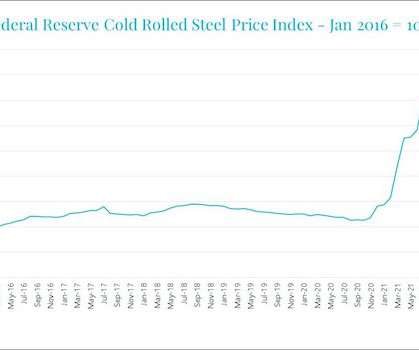

IDTechEx is predicting the automotive lidar market to grow to $8.4 Why lidar is important for automotive applications Various sensors are essential to enable ADAS and AV systems, including cameras, radars, ultrasonic systems, etc. The installation location and cleaning strategies are also discussed for actual adoption.

Let's personalize your content