End-to-End Digital Manufacturing Demonstration

Automation World

SEPTEMBER 28, 2022

Siemens shows how a part or product can be made entirely in one closed-loop digital environment to optimize the entire process before production begins.

This site uses cookies to improve your experience. By viewing our content, you are accepting the use of cookies. To help us insure we adhere to various privacy regulations, please select your country/region of residence. If you do not select a country we will assume you are from the United States. View our privacy policy and terms of use.

Automation World

SEPTEMBER 28, 2022

Siemens shows how a part or product can be made entirely in one closed-loop digital environment to optimize the entire process before production begins.

E&T

FEBRUARY 20, 2023

According to industry body Make UK , this permanent increase to the AIA will be most welcome, particularly to smaller manufacturers, “who will now be able to make long-term plans to invest in critical areas of their business, from automation to improving energy-efficiency and self-generation.”

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Manufacturing Sustainability Surge: Your Guide to Data-Driven Energy Optimization & Decarbonization

i4.0 today

APRIL 19, 2023

In these testing times, how can manufacturers transform their operations to meet customer demands and thrive in today’s as well as tomorrow’s marketplace? This is the question that Hartmut Pütz, President – Factory Automation EMEA at Mitsubishi Electric Europe B.V., pcM42zBRSRU. Today Magazine.

Control Engineering

FEBRUARY 10, 2023

ZF Group technology domains include vehicle motion control, integrated safety, automated driving and electric mobility, as explained at the 2023 ARC Industry Forum, organized by ARC Industry Forum. ONLINE [link] The post Digital manufacturing, smart manufacturing, enable sustainability efforts appeared first on Control Engineering.

Design World

OCTOBER 20, 2022

The launch of My Equipment Digital enables new functionality with digital collection and updating of industrial automation asset data through the use of network-based devices. The digital collection method includes firmware information and a one-time vulnerability assessment.

Control Engineering

NOVEMBER 11, 2023

Learning Objectives: Understand what technologies should be integrated into manufacturing automation and robotic processes Review current, available Industry 4.0 technology trends Learn the needed competences to complete a robotics and automation risk assessment Quickly establish Industry 4.0 To thrive within the Industry 4.0

Metrology

JUNE 11, 2023

Rockwell continues to leverage PTC software as an important component of its global customers' digital manufacturing solutions. The post PTC and Rockwell Automation Extend Relationship with Focus Augmented Reality for Manufacturing appeared first on Metrology and Quality News - Online Magazine.

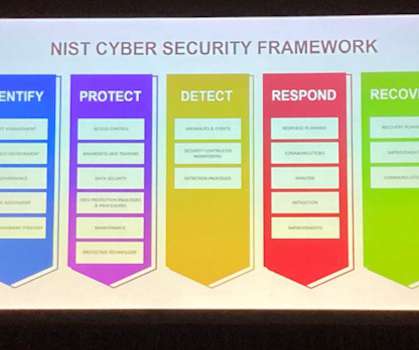

Control Engineering

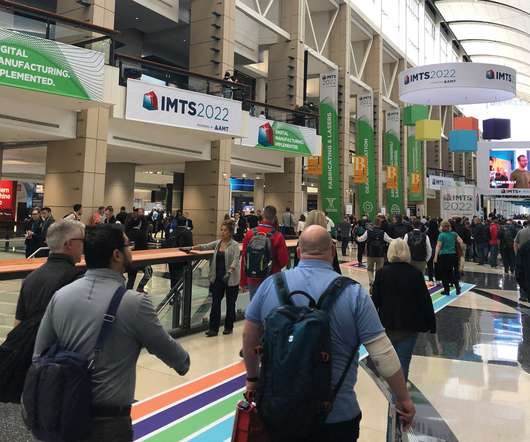

SEPTEMBER 14, 2022

While the majority of the sessions centered around digital and traditional manufacturing – from 3D printing to drilling and grinding – there was an element of cybersecurity on the show floor, as well. Why do cyber criminals target the manufacturing supply chain? According to Elan, manufacturing is the No. On Monday, Sept.

Cisco Industrial Automation

APRIL 27, 2022

Digital manufacturing stresses factory networks in ways their designers never dreamed of. You might be pulling ahead of competitors using cloud applications like predictive maintenance or “digital twins” that simulate the effects of changes. By some accounts, manufacturing was the most attacked industry in 2021.

Robotics Automation News

NOVEMBER 1, 2022

Bright Machines, a startup which describes itself as “an innovator in software-defined manufacturing”, has raised $132 million in debt and Series B equity funding. The equity portion of the funding, worth $100 million, was led by Eclipse Ventures.

Canadian Manufacturing

OCTOBER 25, 2022

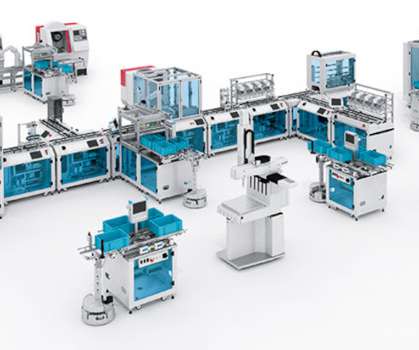

Vention’s Manufacturing Automation Platform (MAP) – from the design to deployment (CNW Group/Vention). MONTREAL — Vention, a digital manufacturing automation platform (MAP), has officially announced the launch of its new software-assisted deployment digital twin, MachineCloud.

Fabricating & Metal Work

SEPTEMBER 23, 2022

ProShop ERP , the leading supplier of digital manufacturing management systems and Datanomix , the leader in Automated Production Intelligence , announced a partnership to help manufacturers deliver more insights from their operational data. www.proshoperp.com. www.datanomix.io.

Modern Machine Shop

FEBRUARY 6, 2023

Photo Credit: Getty Images AMT – The Association For Manufacturing Technology and Mesago , a subsidiary of Messe Frankfurt Group, announce a collaboration to create an automation sector at The International Manufacturing Technology Show (IMTS) in 2024 and Smart Production Solutions (SPS) in Atlanta, Georgia, in 2025.

Mold Making Technology

JANUARY 24, 2023

Photo Credit: Gardner Business Media The Association For Manufacturing Technology (AMT) and Mesago , a subsidiary of Messe Frankfurt Group, are collaborating to create the Automation Sector at the International Manufacturing Technology Show (IMTS) and Smart Production Solutions (SPS). manufacturing market,” says Woods.

Metrology

MARCH 20, 2024

This year’s agenda will feature experts from the disciplines of 3D scanning, photogrammetry, in-line automation, reverse engineering, quality inspection, precision alignment, and digital manufacturing. The post 40th Annual Coordinate Metrology Society Conference appeared first on Metrology and Quality News - Online Magazine.

Gary Mintchell

DECEMBER 14, 2023

The three role-based copilots—Plant Performance Copilot, Digital Manufacturing Copilot, and the Connected Worker Copilot—provide enhanced human-like interaction so workers can get beyond standard data analytics and analysis to understand what happened, why, and more importantly, anticipate future events.

Manufacturing Tomorrow

NOVEMBER 2, 2023

The two companies are combining capabilities to establish robotics and automation simulation software company, ME Industrial Simulation Software Corporation

Plataine

JULY 4, 2022

In fact, at Plataine, we think that digitalizing your production line is only likely to be successful if all production line operators and managers think in terms of the Lean goals of waste minimization and productivity maximization. Before considering deploying a digital manufacturing solution, it’s vital to plan in advance.

Canadian Manufacturing

APRIL 9, 2024

In joining forces, the two companies will try and enhance the automation of manufacturing processes through the integration of advanced computer vision capabilities. ” Syntax’s Global CTO, Marcelo Tamassia, added, “Our collaboration with Cogniac is set to upgrade the technological landscape for our clients. .

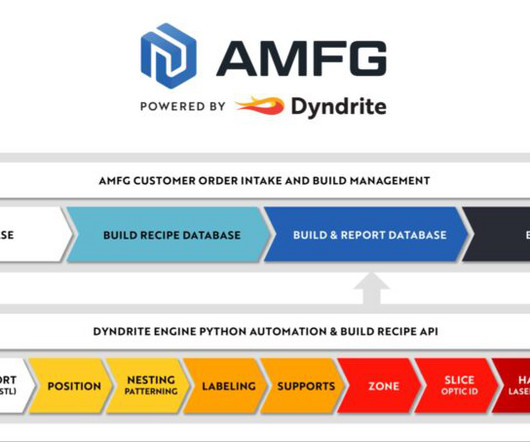

Additive Manufacturing

MAY 1, 2023

Brings automated process-to-part app development capability to metal 3D printing. The integrated solution unlocks the full potential of metal 3D printing by bringing order-to-part automation, eliminating bottlenecks, and streamlining the entire production process for increased efficiency and cost savings.

Manufacturing Tomorrow

JULY 5, 2022

-Next generation manufacturing facilities use breakthrough 100-kilowatt laser additive manufacturing technology, automated machining, integrated robotics, and a proprietary digital thread -VulcanForms serves leading defense, aerospace, medical, and semiconductor companies, supplying precision engineered components and assemblies

Manufacturing Tomorrow

MAY 2, 2023

Expanded materials, software, services and HP Digital Manufacturing Network highlight advancements for customers; Endeavor 3D Offering HP Metal Jet Services

Gary Mintchell

FEBRUARY 21, 2023

The software tool’s source code is available to the PACTware Consortium membership consisting of 22 automation vendors who offer the FDT-enabled hosting product to the user community at no cost. Suppliers of industrial automation systems and devices want to provide solutions that enable the Industrial Internet of Things (IIoT).

i4.0 today

APRIL 25, 2023

Both at the special show “Modular and Open Production” of the German Electrical and Digital Manufacturers’ Association (ZVEI e.V.) The concept of modularization with MTP originated in the process industry but is increasingly being adapted for other industrial sectors, with a high degree of automation.

Automation Mag

MARCH 16, 2023

“Our investment is a significant step in accelerating ABB Robotics’ global leadership in developing and manufacturing cutting-edge robotic solutions in the U.S., for the Americas,” said Sami Atiya, president of ABB Robotics and Discrete Automation. “As for the Americas, streamlining the delivery process and reducing lead times.

iBASEt

FEBRUARY 8, 2024

It lays the groundwork by introducing digital capabilities but does not yet harness the full potential of a model-based approach. Toward Fully Digital Manufacturing Fully digital manufacturing is defined by several key attributes. On the horizon is the Model-Based Enterprise (MBE). billion in 2023 to USD 35.04

Robotics Business Review

MARCH 28, 2024

.” The Taipei, Taiwan-based company explained how its technologies can benefit industrial automation and warehouse operations. Delta designs simulation to manage automation Founded in 1971, Delta Electronics said it is a global leader in switching power supplies and thermal management products. “In 2012, Industry 4.0

Modern Machine Shop

APRIL 7, 2024

has joined ModuleWorks ’ Strategic Partner Program, a collective commitment to driving intelligent and integrated digital manufacturing solutions. As a cutting tool manufacturer, Kennametal extends the variety of partners in the program, thereby further driving the digitalization initiative in the industry.”

Manufacturing Tomorrow

AUGUST 10, 2023

SAEKI is building the flexible factories of the future leveraging digital manufacturing and robotics, providing an end-to-end automation solution in 24 hours.

Automation Mag

MARCH 11, 2024

Based on the agreement, Mitsubishi Electric will integrate its factory automation (FA) equipment and OT security solutions with Dispel’s secure remote-access technology to provide a Zero Trust Remote Access Service that reportedly monitors, controls and verifies remote-access operations involving equipment in manufacturing facilities.

Cisco Smart Manufacturing

APRIL 5, 2017

and smart manufacturing concepts have been around for a few years, thought leaders are now agreeing that Industrie 4.0 In a recent issue of CloudComputing News, this passage was particularly striking: “Manufacturers are gaining the greatest value from Industry 4.0 Even though Industrie 4.0 is at an inflection point.

Fabricating & Metal Work

MARCH 21, 2023

“Our investment is a significant step in accelerating ABB Robotics’ global leadership in developing and manufacturing cutting -edge robotic solutions in the US, for the Americas,” said Sami Atiya, President of ABB Robotics and Discrete Automation. “As Pictured is the Robot Studio entryway.

Modern Machine Shop

APRIL 14, 2024

” will be on the importance of connecting every step of the manufacturing process, from CAM to final part, along the journey to digitization. solutions, why tool management is vital for digital manufacturing and how to engage the future workforce through mentoring, apprenticeships and corporate partnerships.

i4.0 today

NOVEMBER 16, 2023

Through the new company, Mitsubishi Electric plans to enhance its digital twin platform for circular digital-engineering business solutions. “This joint venture allows us to maximize synergy by combining Visual Components’ excellent 3D simulation software with Mitsubishi Electric’s manufacturing expertise.

HGR Inc.

OCTOBER 25, 2022

The history of industrial robots is closely tied to George Devol, whose magnetic recording technology of the 1930s emphasized the need for factory automation. Keep reading to learn more about his immense contribution to industrial automation. What is industrial automation?

Additive Manufacturing

FEBRUARY 21, 2023

UAS Leader Integrates DAPS Digital Manufacturing Process SAN DIEGO – 15 February 2023 – General Atomics Aeronautical Systems, Inc. (GA-ASI), GA-ASI), the world’s leading manufacturer of Unmanned Aircraft Systems (UAS), radars, electro-optic and related mission systems, is partnering with Divergent Technologies, Inc.

Modern Machine Shop

MARCH 28, 2023

Sami Atiya, president of ABB Robotics and Discrete Automation, says, “Our expanded facility will help us to better serve customers in the US and across the Americas, giving them access to innovative automated solutions.” manufacturing hub and headquarters befitting of a global leader in automation. .

Additive Manufacturing

NOVEMBER 20, 2022

The new solutions, badged as PostPro DMS (Digital Manufacturing System), enable a seamless connection between the physical and digital elements of the workflow from design to production to post processing. AMT’s automated loader system is now available to purchase as an upgrade with the PostPro SF 100.

i4.0 today

APRIL 12, 2023

ABB Robotics has been selected by Nobia – the leading kitchen specialist in Europe – to supply robotic automation solutions for their new factory in Jönköping, Sweden. The robots will enable the factory to produce customized cabinets with 75-80% higher efficiency (time) in comparison to non-automated processes.

Fabricating & Metal Work

DECEMBER 20, 2022

The optimism regarding manufacturing is infectious as companies continue to embrace automation and robotics, digital manufacturing (Industry 4.0), and initiatives such as bringing manufacturing back (or plans to research a return) to the United States to prevent supply chain constraints. Implemented.”

Modern Machine Shop

JUNE 13, 2023

The show has included demonstrations featuring robots, cobots, vision systems, as well as other manufacturing processes such as additive manufacturing, CNC machining, metrology and part handling. IMTS 2024 will mark the premier of the Automation Sector, powered by Smart Production Solutions (SPS), which will be in the North Building.

Control Engineering

MARCH 16, 2023

“Our investment is a significant step in accelerating ABB Robotics’ global leadership in developing and manufacturing cutting -edge robotic solutions in the US, for the Americas,” said Sami Atiya, president of ABB Robotics and Discrete Automation in a press release. “As

Fabricating & Metal Work

JANUARY 3, 2024

Welcome to 2024 where the road to digital manufacturing, cybersecurity and AI is paved with endless possibilities. Industry experts say the best advice is to start slowly and experience a “win” where you can see the value of utilizing digitalization, cybersecurity, automation and AI in your manufacturing processes.

Control Engineering

OCTOBER 10, 2022

On day 2, October 18, of the Fall 2022 session of CFE Media’s Virtual Training Week, Ted Rozier, director of engineering at the Mason, OH-based Festo Didactic Solution Center, North America, will present on the topic of “ How to unleash the power of Smart Manufacturing while ensuring automation and robotic safety. ”. technology trends.

Expert insights. Personalized for you.

We have resent the email to

Are you sure you want to cancel your subscriptions?

Let's personalize your content