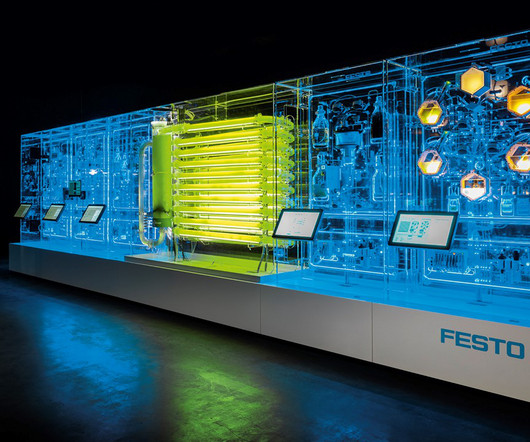

Universal automation lays the foundation for smart factories

Control Engineering

JANUARY 4, 2023

Learn how IEC 61499 and IEC 61131-3 are impacting universal automation. Learn about universal automation’s benefits and how technology such as Ethernet-APL and edge devices will improve users’ intelligence. Smart factory and automation insights. and Industrial Internet of Things (IIoT) applications. They are not alone.

Let's personalize your content