SoMAC CRC executes first Australian space research project

Manufacturer's Monthly

JUNE 27, 2023

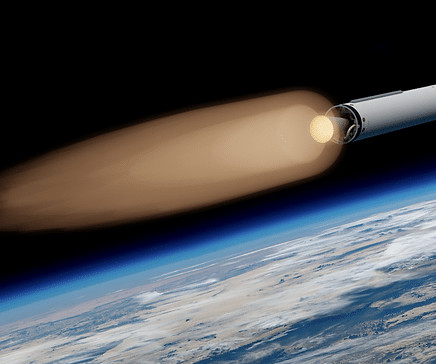

Through the execution of its first-ever project, the Sovereign Manufacturing Automation for Composites CRC (SoMAC CRC) could unveil a new cost-effective solution for protecting launch vehicles and spacecraft against extreme heat and pressure. SoMAC CRC commenced operations in January 2023.

Let's personalize your content