What does it take to truly achieve smart manufacturing in Asia Pacific?

AU Manufacturing

MARCH 5, 2023

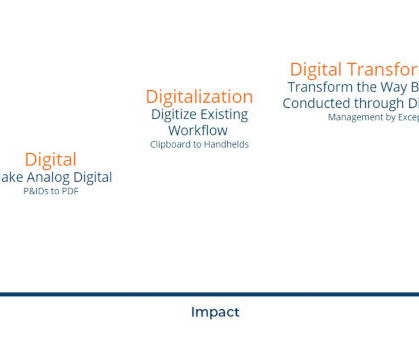

To increase competitive advantage, many manufacturers in Asia Pacific are hoping to capitalise on “smart manufacturing” – the concept of integrating technologies, data, processes, and human interactions to improve production results. This, is the future of smart manufacturing. Yet, there are two key barriers.

Let's personalize your content