Stability Maps for Milling

Modern Machine Shop

FEBRUARY 23, 2025

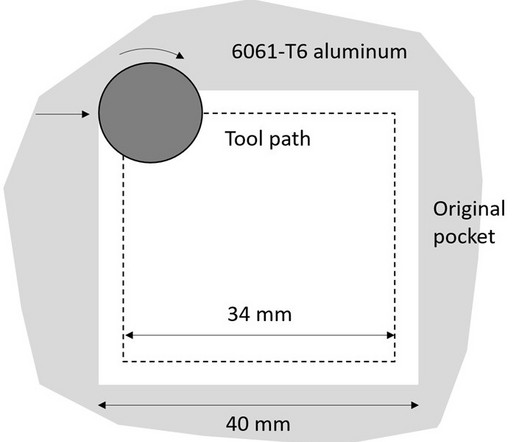

Milling instability, or chatter, is one factor that limits material removal rates, because the stable depth of cut is restricted by the system dynamics. Using stability maps, however, stable combinations of spindle speed and axial depth of cut can be selected. tool paths. Because material is removed layer-by-layer in 2.5D

Let's personalize your content