Robotics innovation is key to reshoring the $1T apparel manufacturing industry

Robotics Business Review

APRIL 5, 2024

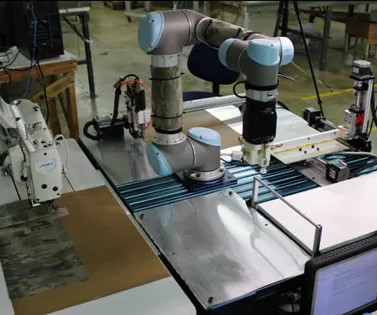

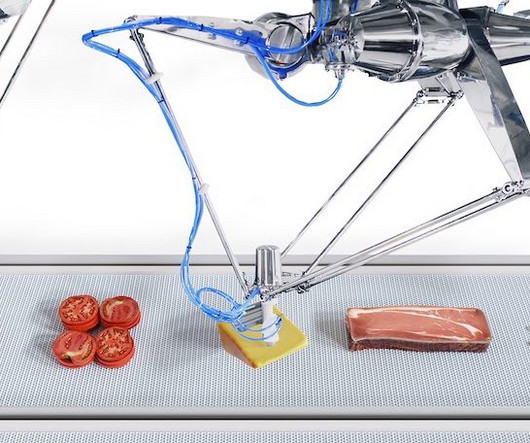

The polymer used in the stiffening process is easily removed through washing and can be recycled for multiple process cycles. While the garments project took a huge step towards proving the viability of robotics in clothing manufacturing, it had a higher cycle time than current manual processes. Development didn’t stop there.

Let's personalize your content