Taking a dynamic approach to safety

Control Engineering

FEBRUARY 24, 2023

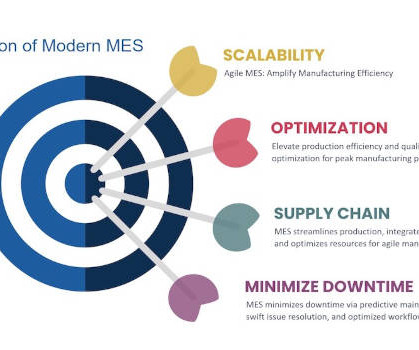

A third scenario example looks at process optimization, where operational downtime and bottlenecks may not pose a risk to humans, property and the environment, but they can affect system performance. This necessitates a digital or virtual representation of the physical manufacturing system, using digital twins and asset administration shells.

Let's personalize your content