Pulse Technology and Software Power Laser Machining Popularity

Fabricating & Metal Work

DECEMBER 8, 2023

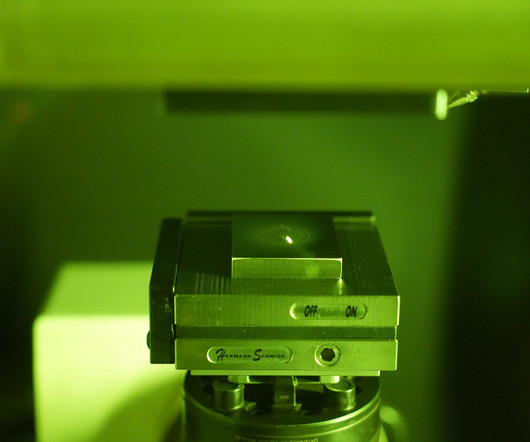

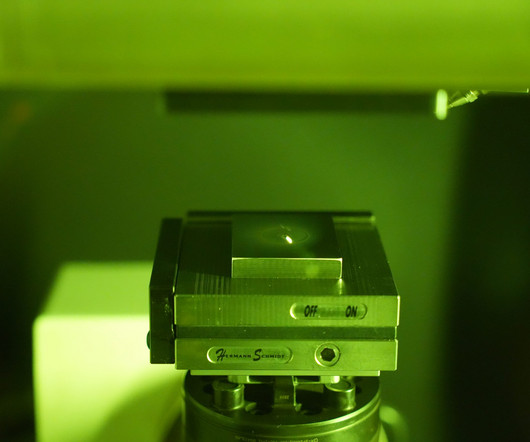

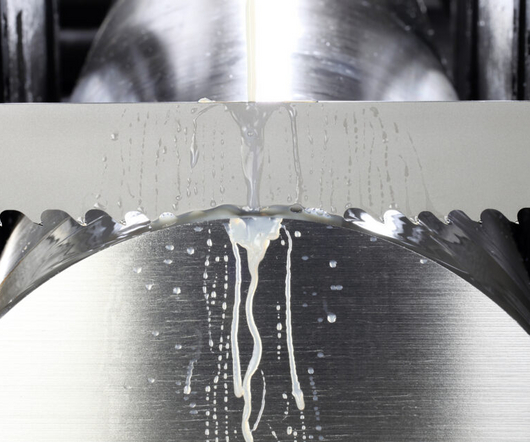

While one can debate whether technological advance drives demand or vice versa, it’s clear that the evolution in laser sources/pulse technology and software control have moved laser manufacturing technology to the tip of the spear. In the past decade, the industry, in particular, has seen dramatic strides in laser source innovation.

Let's personalize your content