Thermal Loop Solutions: A Path to Improved Performance, Sustainability and Compliance in Heat Treatment

MEM

JUNE 15, 2023

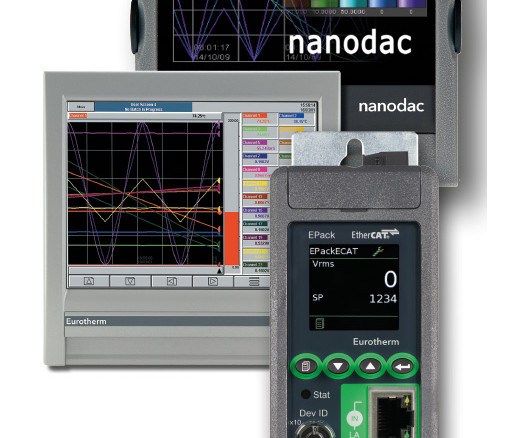

A thermal loop solution is a closed loop system with several essential components, including an electrical power supply, power controller, heating element, temperature sensor and process controller. NADCAP heat treatment accreditation ensures suppliers meet industry standards and best practices for heat treatment processes.

Let's personalize your content