Watch Out adds autonomy to CNC cells for precise production

Robotics Business Review

JANUARY 21, 2025

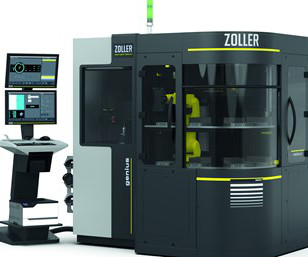

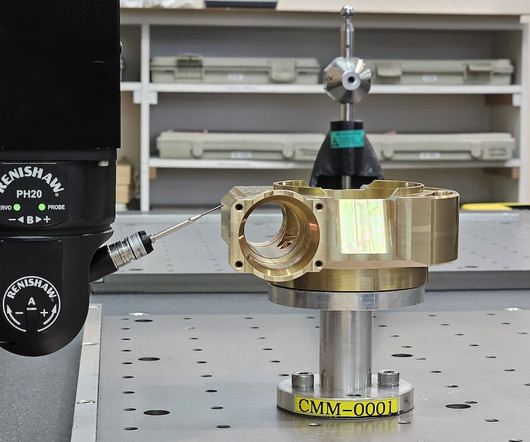

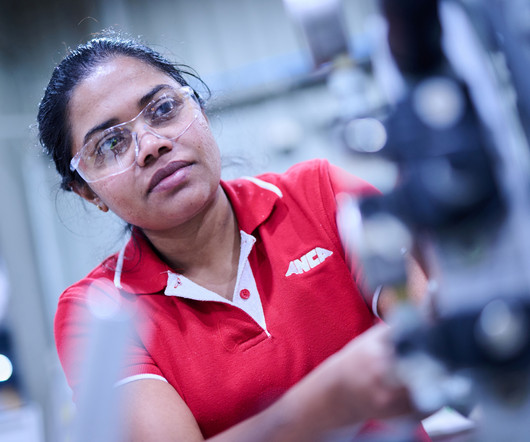

Watch Out visualizes a highly automated workcell that can fit into a container. Source: Watch Out Manufacturers face widespread shortages of skilled labor, but more intelligent automation could alleviate the problem, according to Watch Out. It has workshops in Bonneville, France, and Dorval, Canada.

Let's personalize your content