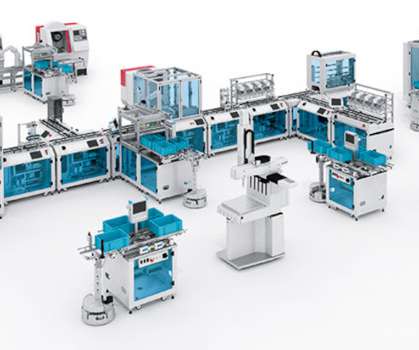

Unleash the power of smart manufacturing while ensuring automation and robotic safety

Control Engineering

NOVEMBER 11, 2023

Learning Objectives: Understand what technologies should be integrated into manufacturing automation and robotic processes Review current, available Industry 4.0 technology trends Learn the needed competences to complete a robotics and automation risk assessment Quickly establish Industry 4.0 To thrive within the Industry 4.0

Let's personalize your content