Highlights from the Advanced Manufacturing Readiness Facility Showcase 2024

Manufacturer's Monthly

DECEMBER 3, 2024

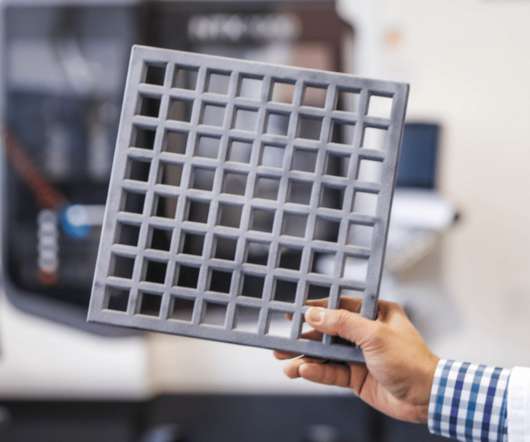

Image: Prime Creative Media This morning marked a milestone in the journey towards the opening of Bradfield’s Advanced Manufacturing Readiness Facility (AMRF), a hub that accelerates innovation by providing businesses with advanced technology, expertise, training, and networks to grow faster, reduce risks, and compete globally.

Let's personalize your content