Disruptive Technologies in Automotive and Aerospace Manufacturing Unlocking New Growth Avenues

Frost & Sullivan Manufacturing

JUNE 10, 2025

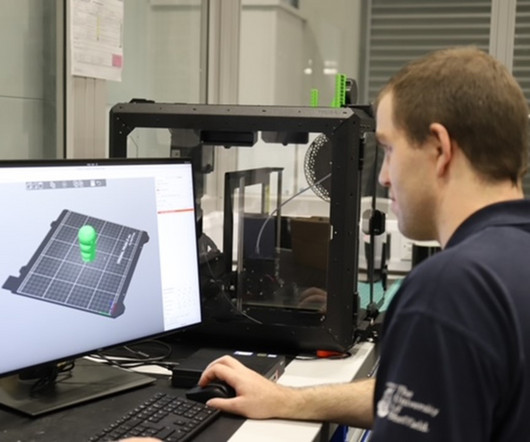

As the global demand for cleaner, smarter transportation surges, automotive and aerospace manufacturers are racing to innovate and adapt in an increasingly complex and competitive environment. Additive Manufacturing: Revolutionizing prototyping and small-batch production with cost-effective precision.

Let's personalize your content