Multiple AI models help robots execute complex plans

Robotics Business Review

JANUARY 15, 2024

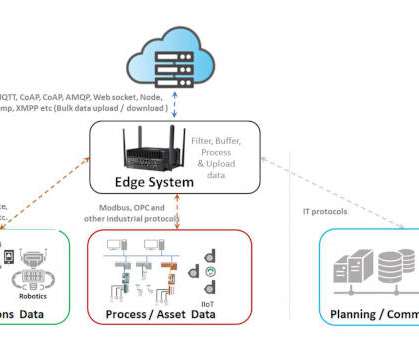

The HiP framework develops detailed plans for robots using the expertise of three different foundation models, helping it execute tasks in households, factories, and construction that require multiple steps. Submit your nominations for innovation awards in the 2024 RBR50 awards.

Let's personalize your content