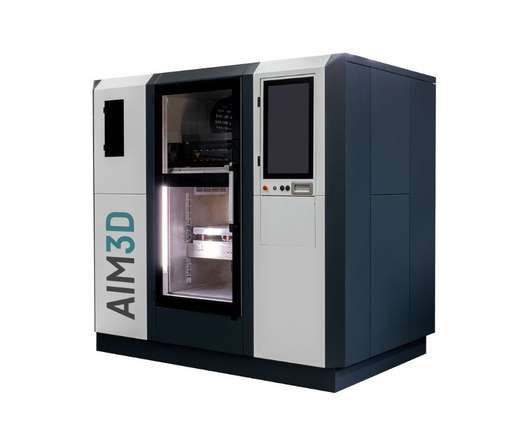

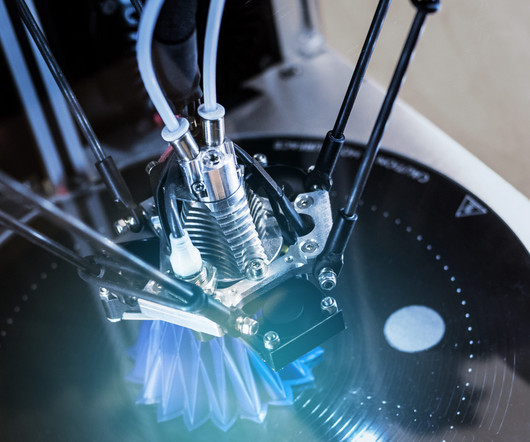

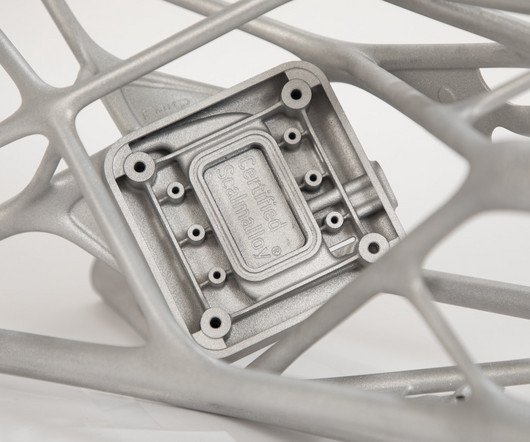

The next step towards industrial production using metal 3D printing

Design World

AUGUST 28, 2024

Presenting the next generation of wire-laser metal deposition technology. The Meltio M600 metal 3D printer makes printing large metal parts easier and more reliable than ever while being tailored perfectly to the needs of industrial manufacturing with 24/7 production cycles.

Let's personalize your content