An Integrated Desktop Approach to Mold Production

Mold Making Technology

NOVEMBER 28, 2024

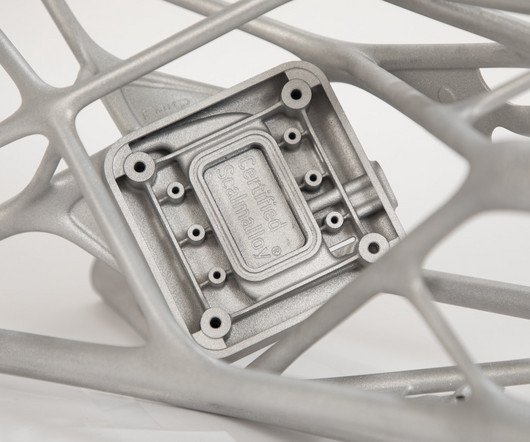

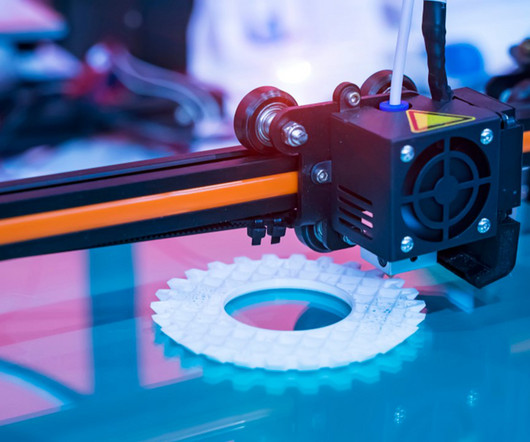

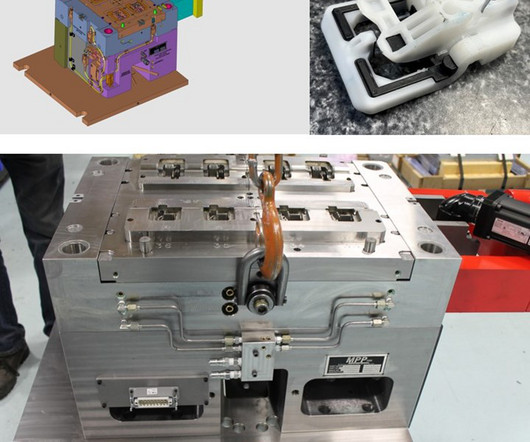

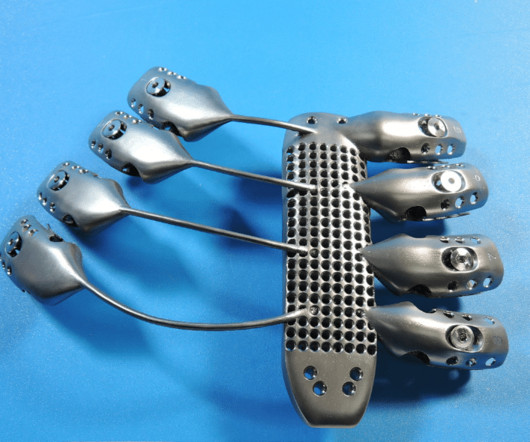

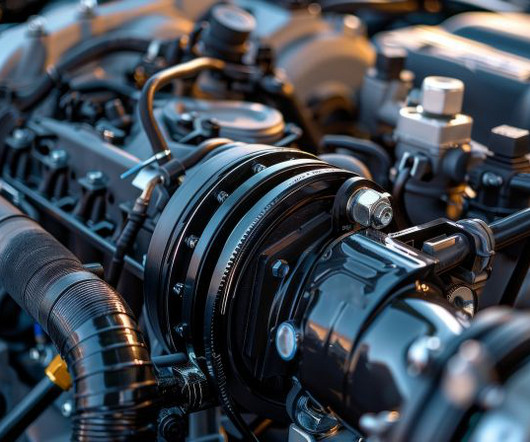

A mold produced on a desktop resin 3D printer. Source (All images) | APSX As moldmakers face increasing pressures to deliver faster and more cost-effective solutions, integrating 3D printing (3DP), machining and desktop injection molding into the process can offer significant advantages for both novice and advanced moldmakers.

Let's personalize your content