3D Printing in Medical Devices: Leveraging a Digital Manufacturing Partner

iBASEt

JUNE 7, 2022

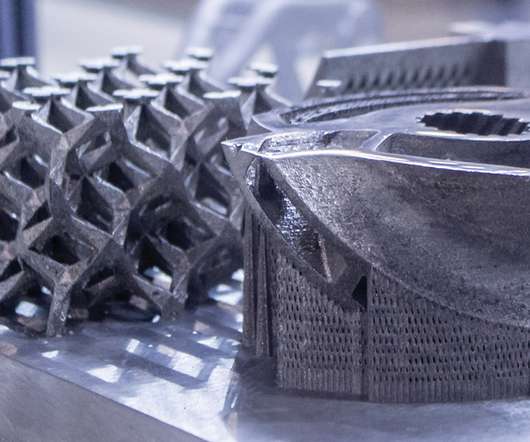

When you think of a hospital printing organ implants and creating custom joint replacements in a matter of hours, you might be picturing a scene decades from now. Thanks to 3D printing, that reality is only a handful of years away. This is just one example of the potential impact of 3D printing.

Let's personalize your content