New Report Signifies Disruptive 3D Printing Technology Set to Break into Mainstream Production

i4.0 today

OCTOBER 18, 2022

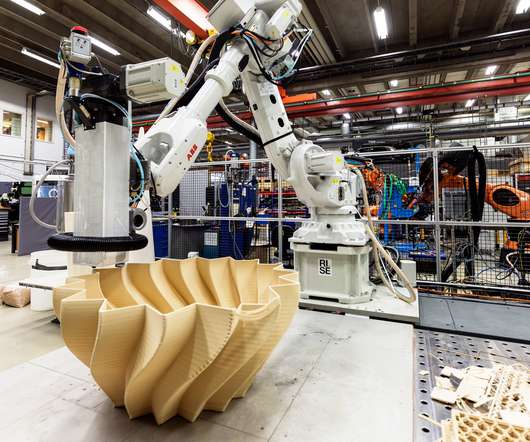

Composite-based additive manufacturing appears to be on the verge of breaking through as a ‘mainstream’ method of production, according to a new report on disruptive 3D printing technologies. Current 3D printing simply cannot deliver the level of precision and material strength required for these applications.

Let's personalize your content