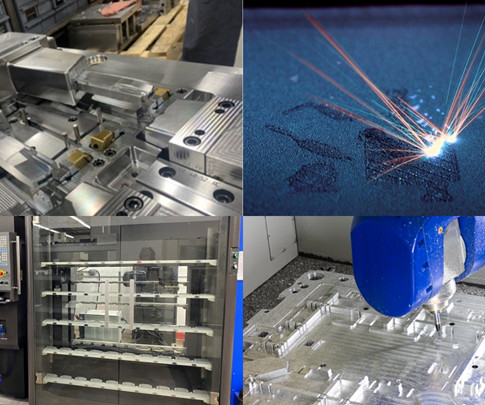

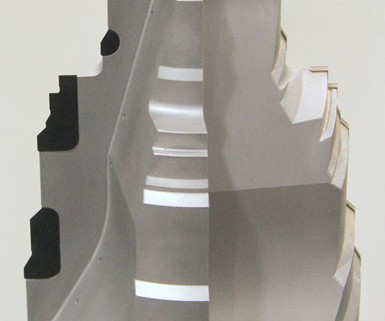

Schwanog's Custom Form Tools Reduce Cycle Times

Modern Machine Shop

APRIL 18, 2023

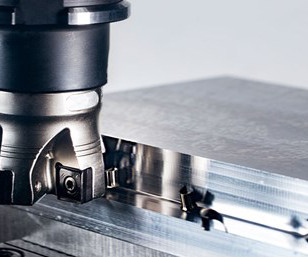

These tools, which are manufactured in the United States, can reduce cycle times by as much as 40%, according to the company. They are designed to offer high quality and machining efficiency in the manufacture of precision parts for industries such as medical, automotive, aerospace and others.

Let's personalize your content