Keys to the efficiency of job shop manufacturing businesses

Manufacturer's Monthly

FEBRUARY 6, 2025

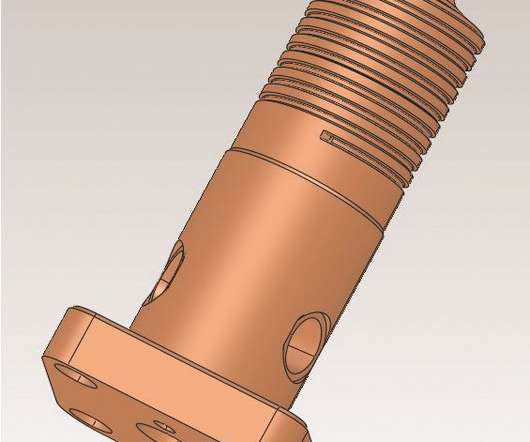

Image: ECI Solutions The job shop manufacturing sector in Australia is a significant part of the overall manufacturing industry, creating unique products with tailored specifications. However, job shop manufacturers face a variety of challenges that can impact efficiency and customer satisfaction.

Let's personalize your content