AML3D announces push for aerospace components certification

AU Manufacturing

JULY 24, 2022

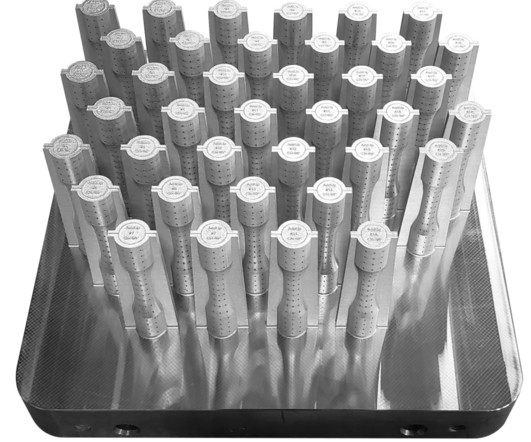

Wire Additive Manufacturing (WAM) developer AML3D has begun processing its compliance with the AS9100D:2016 quality systems accreditation for its proprietary manufacturing technology. .

Let's personalize your content