3D printing — driving business in the automotive sector

AU Manufacturing

SEPTEMBER 13, 2022

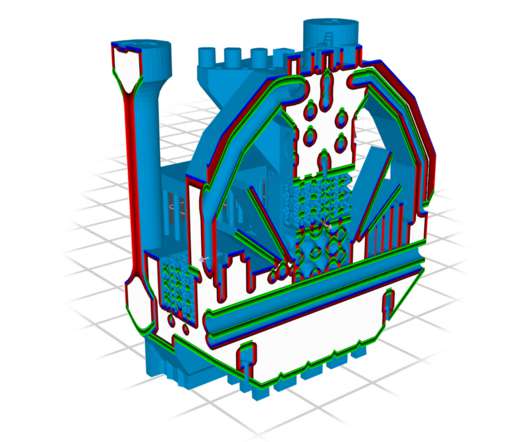

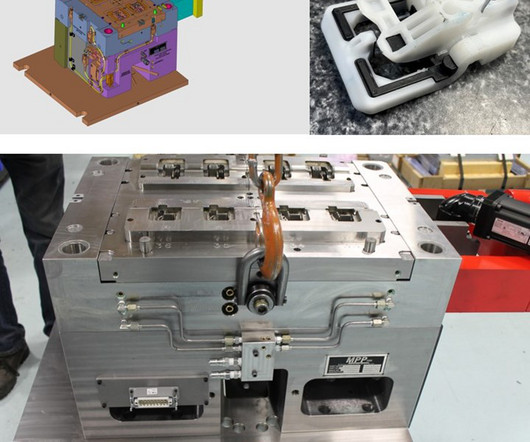

The automotive sector is driven by the need for quality parts, delivered in a timely fashion, and at a competitive price. As such, for various applications, 3D printing is a good fit, allowing the manufacture of impossibly complex geometries in a variety of robust materials in a speedy and cost-effective fashion.

Let's personalize your content