Partnerships Fuel Moldmaker’s Growth in Technology and Training

Mold Making Technology

JANUARY 1, 2025

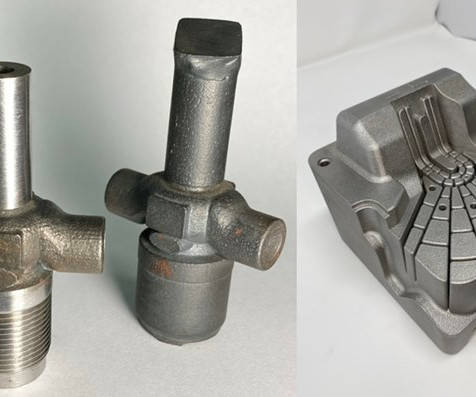

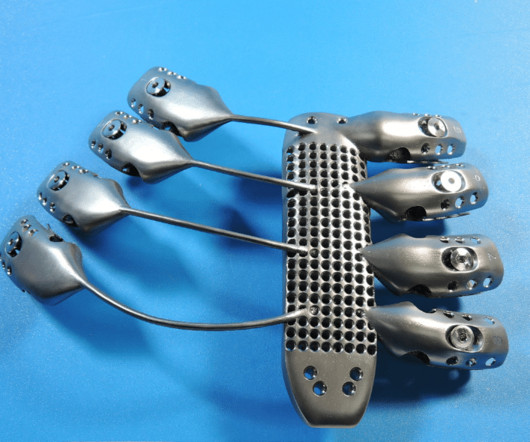

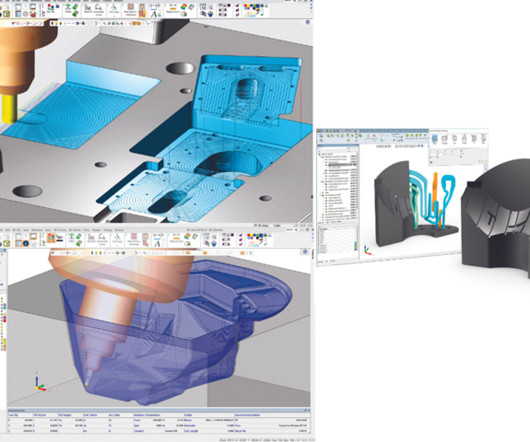

Serves the electronics, medical, appliance, fluid power, marine, consumer products, construction, aerospace, automotive, electrical, mechanical, pharmaceutical and computer components industries. ISO 9001-2015 and ISO 14001:2015-certified. Advanced software and high-speed machining techniques significantly reduce lead times.

Let's personalize your content