AML3D to deliver prototype parts for BAE Systems

Manufacturer's Monthly

OCTOBER 26, 2022

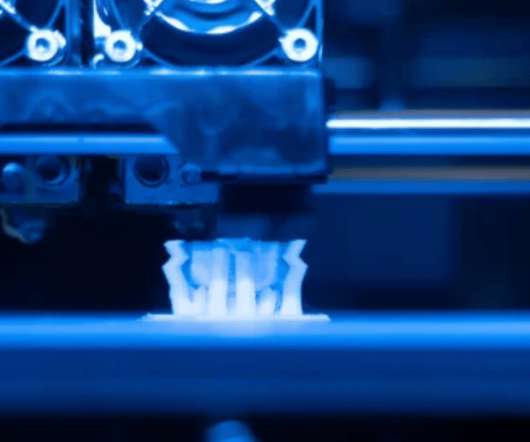

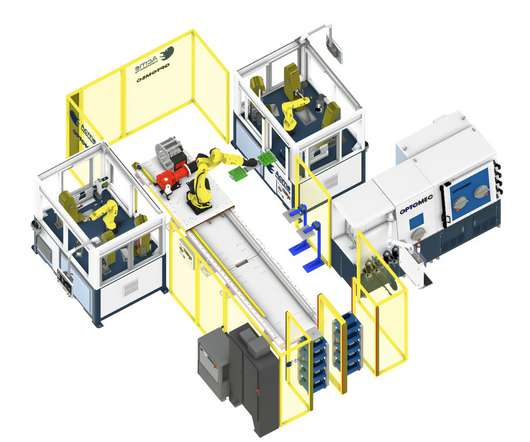

The validation testing demonstrated AML3D’s WAM® technology as a cost-effective manufacturing solution with the potential to minimise lead times and meet BAE Systems Australia’s internal standards for additive manufactured components.

Let's personalize your content