AML3D to deliver prototype parts for BAE Systems

Manufacturer's Monthly

OCTOBER 26, 2022

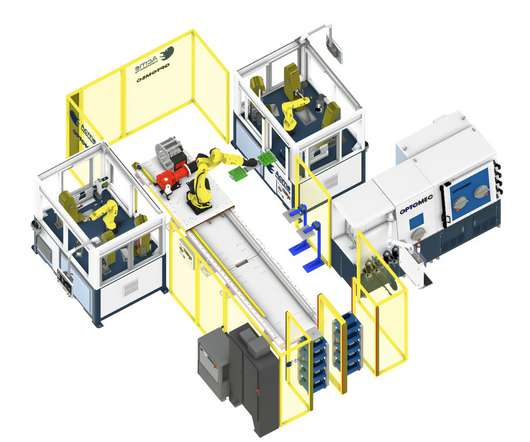

The validation testing demonstrated AML3D’s WAM® technology as a cost-effective manufacturing solution with the potential to minimise lead times and meet BAE Systems Australia’s internal standards for additive manufactured components. AML3D utilises new technologies to pioneer and lead metal additive manufacturing globally.

Let's personalize your content