Motoring into the IE5 era for energy efficiency

E&T

MARCH 14, 2023

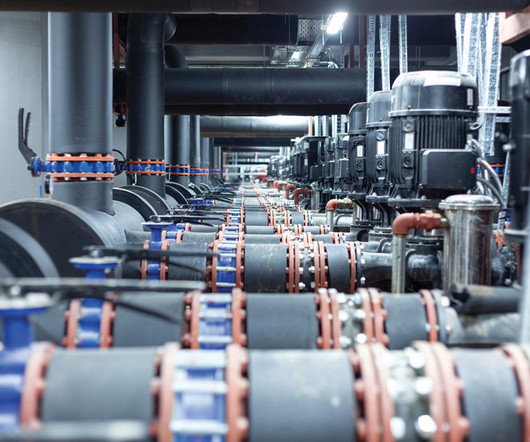

Industrial motors are used to control torque and speed on conveyor belts, robotic arms, automated guided vehicles and in compressors to regulate the volume of air, gas or liquid running through pipes. Unfortunately, on top of an energy crisis, there is also a supply crisis, says Hanigovszki, with lead times of around six months for motors.

Let's personalize your content