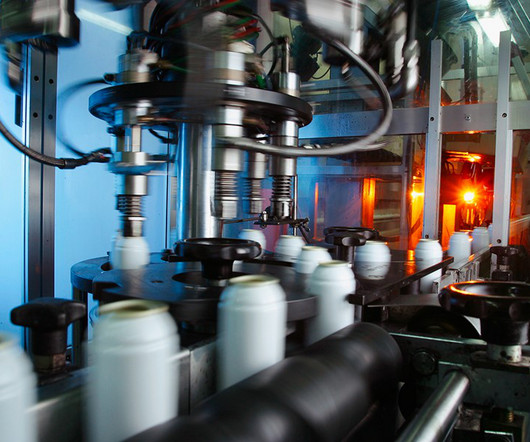

Top 8 Imperatives Reshaping Industrial Automation in 2025

Frost & Sullivan Manufacturing

APRIL 7, 2025

These hubs unite companies, governments, and researchers to develop cutting-edge automation solutions, standardize best practices, and accelerate the deployment of next-gen robotics. Robots, IoT devices, and cloud systems are now operating with near-zero latency, enabling hyper-efficient factory synchronization.

Let's personalize your content